What we do

Since Ingenia was founded in 1998, we have specialised in tackling unique and specially commissioned production line automation problems. In addition to creating bespoke special purpose machines, we offer customised automated box filling solutions and conveyor systems. We can also create high quality custom made products using aluminium extrusion.

After years of offering innovative, technically superior, brilliantly engineered bespoke solutions that give great value for money with optimum performance, we now also offer ‘off the shelf’ products based on increasing demand for this type of automation, such as box packing machines and cut coil band machines.

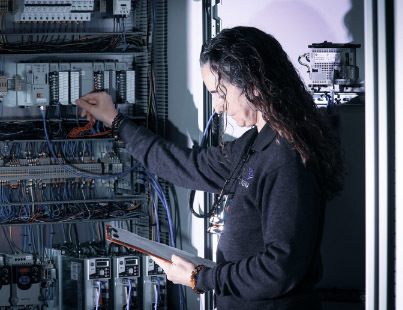

With our extensive in-house design and build capabilities, we can create the machines we design for you ourselves, enabling us to keep control of the quality, lead times and budget. This means you receive outstanding service, unbeatably quality and superb reliability all delivered on time and at a great price.

Our services

Special purpose machines

When there are no machines available that meet your automation requirements perfectly, our inventors can create a one off or limited run of machines to do exactly what you need them to.

Whether you need to adapt an existing machine for a new purpose or require a brand new process to get the job done, we can work with you to create a unique product to complete the task as efficiently, reliably and cost effectively as possible.

Because we have such extensive in-house design and manufacturing capabilities, we can manage everything from coming up with a solution for what you want to achieve to delivering the finished product and helping you maintain it.

All we need from you is what you want to achieve and how you like to work. We can do the rest.

Automated box filling systems

One of our box filling machines, the RBX20, was so successful that we now produce it as a series unit. It proved so popular because users can easily change the settings to allow for different box, carton and fill sizes at the push of a button. Eliminating the need for retooling saves you time and reduces the risk of breakdowns.

We can configure this very versatile design to suit your application or design and build you a completely new system if required. Because time and space are at such a premium in manufacturing and distribution, all our box filling machines are designed with reliability while keeping the footprint as small as possible in mind.

If you have a need to automate your box filling operations, speak to us and we can help you find the ideal solution for your business.

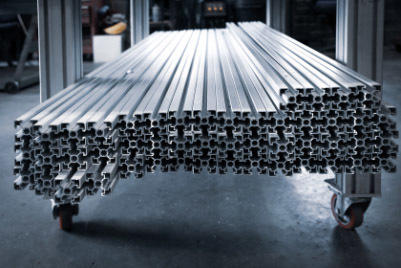

Bosch Rexroth aluminium profile-based products

Using Bosch Rexroth’s aluminium extrusion technology, we create aluminium profile-based products very quickly with little or no waste.

The applications are many and varied ranging from workstations, tables, guarding, frameworks, tower structures and machine bases to material flow systems such as modular conveyors and palletised conveyors.

This very versatile manufacturing system means we can produce custom built products which are robust, rust resistant and built to your exact specifications in a fast and cost-effective way.

Whether you need large numbers of the same product or just one, we can work with you to design and build a product which is ideal for your needs and budget.

Conveyor systems

The conveyor systems we design and build are customised to do exactly what our customers need them to.

Because we generally use these conveyor systems to integrate into existing production lines or to connect equipment we supplied to other machines, we can offer either gravity, driven, roller or belt conveyors depending on which would be most appropriate for the application.

Our products

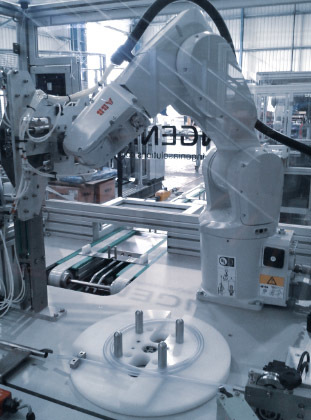

The remarkable RBX20 robotic box filling machine

Click to watch the video

2m 45s

The latest addition to our extensive suite of automated products, it’s a remarkable robotic box filling machine able to transform your production line.

Wide range of box sizes

We’ve taken ten years to develop and fine tune the RBX20, resulting in a uniquely versatile solution that adapts to a wide range of box and carton sizes.

No tooling changes, no delays!

Its flexibility and automation avoid retooling, save valuable downtime, boost production, improve safety and reduce carbon footprint.

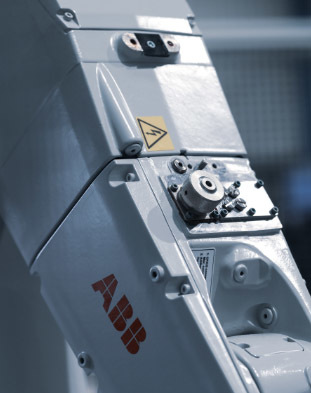

State-of-the-art robotic handling

The 6-axis ABB robot provides continuous and reliable performance and the collator section doesn’t need any adjustments or recalibration. A recipe-based menu display lets you control different box, carton and fill sizes with a set of clear and easy options.

Compact footprint

The box assembly and filling process is contained within the RBX20 cell, which is compact, taking up minimal floor space and there’s no need to store additional change-parts or tools. It also makes it very easy to ship and install by our qualified engineers, wherever you are located.

To find out how the Ingenia RBX20 can make your production line more efficient and profitable, talk to our team today.

The MediTuber 600

Our cut, coil, band machine for medical tubing

Have medical tubing cut to any required length, coiled, bound and ready to bag up and send quickly and efficiently with this easy to operate and reliable machine.

It can cut, coil and wrap adhesive tape around medical tubing sized between 1.5mm to 10mm. They can then be packed into bags and used in operating theatres and emergency medical situations.

This compact machine cuts, coils and bands up to 600 products an hour and its settings can be changed easily to cut different lengths without requiring any retooling.

We developed the first of these machines as a custom design for one of our customers. In the years since we have seen a steady increase in demand for similar systems and have refined and perfected them to fulfil the cut, coil and band functions efficiently and reliably.

We are now offering the MediTuber 600 as a series unit. Talk to our team for more details.

Bosch Rexroth aluminium profile-based products

As a Bosch Rexroth Systems Integrator we can assist you when selecting the correct components for your application, which can then be quickly assembled and delivered from either our stock, direct from Bosch in the UK or from Germany.

Bosch Rexroth offers decades of experience and unbeatable flexibility when designing your assembly line, with the world’s largest aluminium profile building system, which has been continuously developed over more than 30 years.

The robust and corrosion-resistant Rexroth profiles allow you to realise components such as ergonomic worktables, flow racks, or protective guards within a short time and without having to spend great effort on planning. Ergonomic, versatile, productive, and a safe investment: The aluminium profile system from Bosch Rexroth helps you to design complete assembly systems with all the necessary applications exactly according to your needs.

All parts of the system are not only compatible with each other, but are reusable and can be easily used for modifications and extensions, if required.

Utilising the Rexroth system’s wide selection of square and round tubes, installation-friendly connection technology, and wealth of accessories, we design ergonomic, efficient, and safe working environments that open up every conceivable free space.

To find out which of our aluminium profile based products would best suit your application, speak to one of our team and we can provide you with the complete solution you need.